How to choose a tablet machine

The application field of UV flatbed machine is very extensive, and many users have asked how to buy flatbed machine. Here, users in different fields will analyze it from two aspects: users themselves and equipment factories.

First, the users themselves

1. Purchase budget. The price of UV flat-panel printers in the market is roughly divided into four levels:

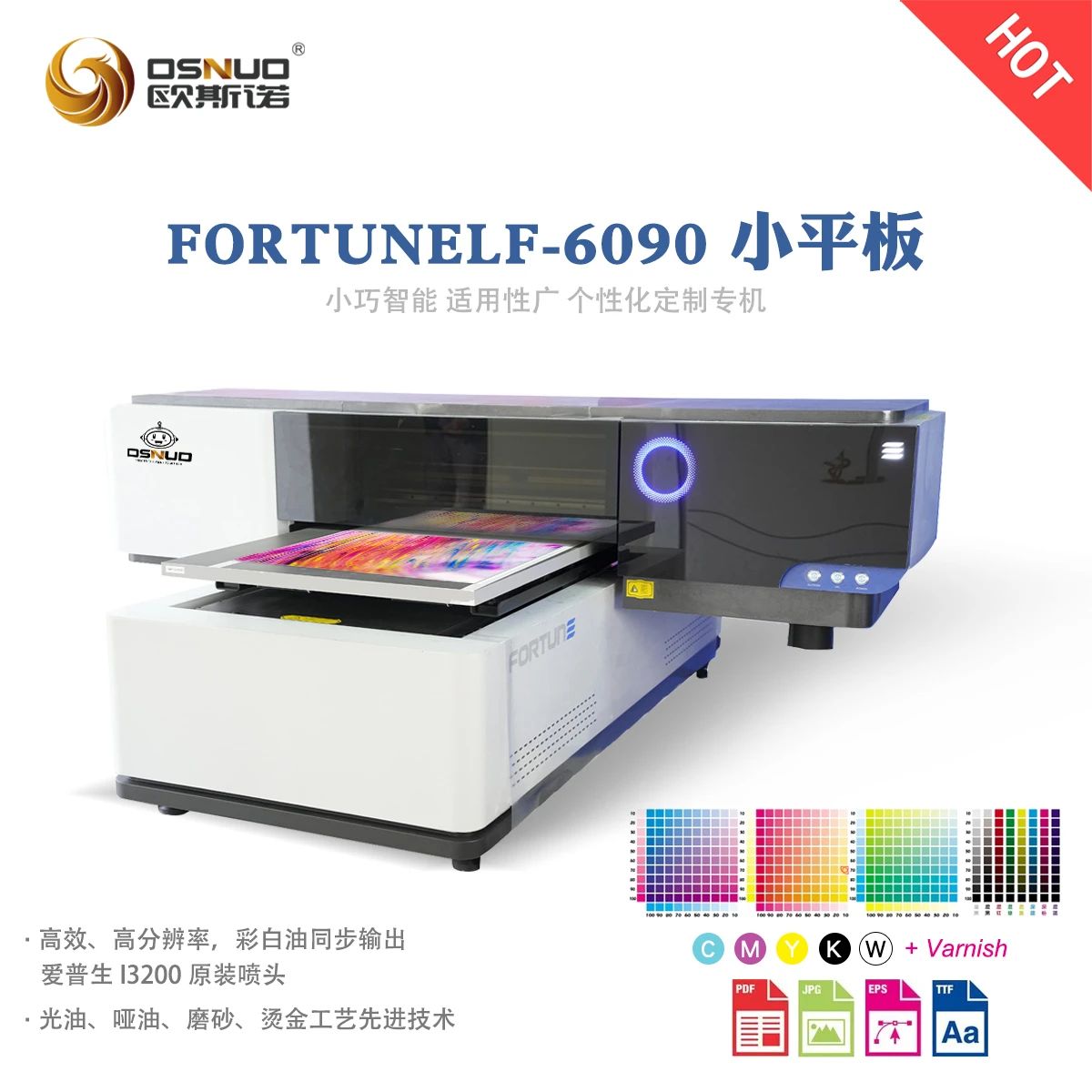

Within 50,000-150,000 yuan, most of them are civil series UV flat-panel printers, and the common models are A3, 6090, 7590, 1325, 1610, 2513 and so on. The nozzles are mostly medium-level brands of Epson, Toshiba, Konica and Seiko series. Generally speaking, it is suitable for individuals to choose small-scale high-profile or large-scale low-profile. At the same price, it would be better to choose high allocation;

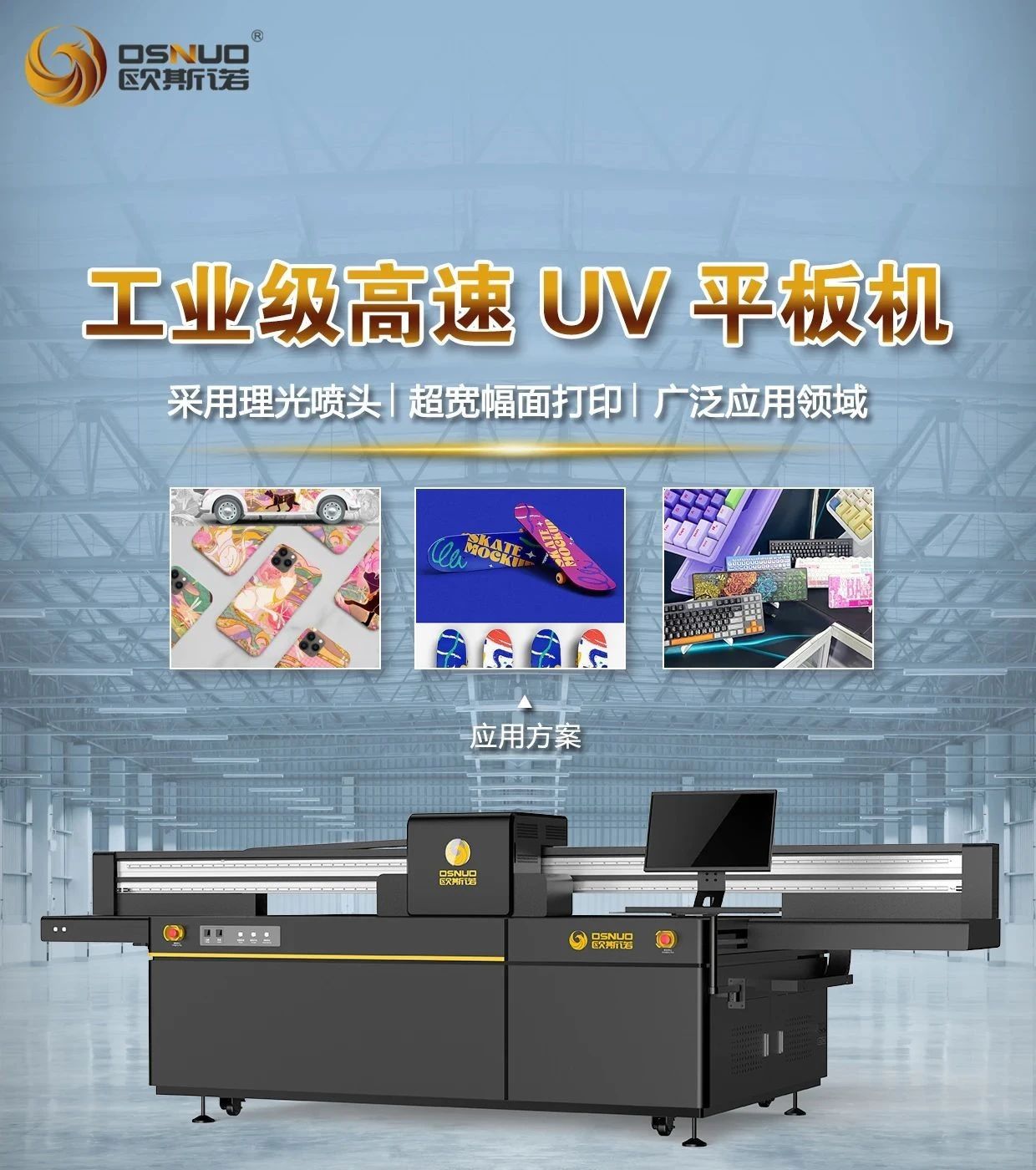

About 200,000, mostly industrial UV flat-panel printing series. At present, the number of equipment and users in this price range is the largest in the market. The machine models are 1610, 2513, 3020, 2533, 3040 and so on. Common nozzles are Ricoh g6, Konica 1024i, Seiko gs1024 and Kyocera. According to the price, the nozzle configuration can be upgraded from the standard five to eight.

More than 250 thousand or even 100 million, mostly large-scale high-equipped or imported UV flat-panel printers. High configuration refers to a high level of nozzles, a large number of nozzles or a particularly large machine format. The number of nozzles of this model is generally more than 16. It is said that the highest number of nozzles in the industry has reached 256 at present, of course, the price is in the tens of millions.

2, the material itself

Material area: determines the size of the selected equipment. In the advertising industry, the standard KT board size is 2.4m×1.2m, and the flat-panel machine with 2513 format and the printing area of 2.5m×1.3m can cover the whole board. Other fields are larger than the width of the material can be customized model;

Material thickness: the printing height of standard model UV flat-panel printer is less than 10cm, and it needs to be customized if it exceeds 15cm, so the corresponding cost will increase and the delivery cycle will be delayed appropriately;

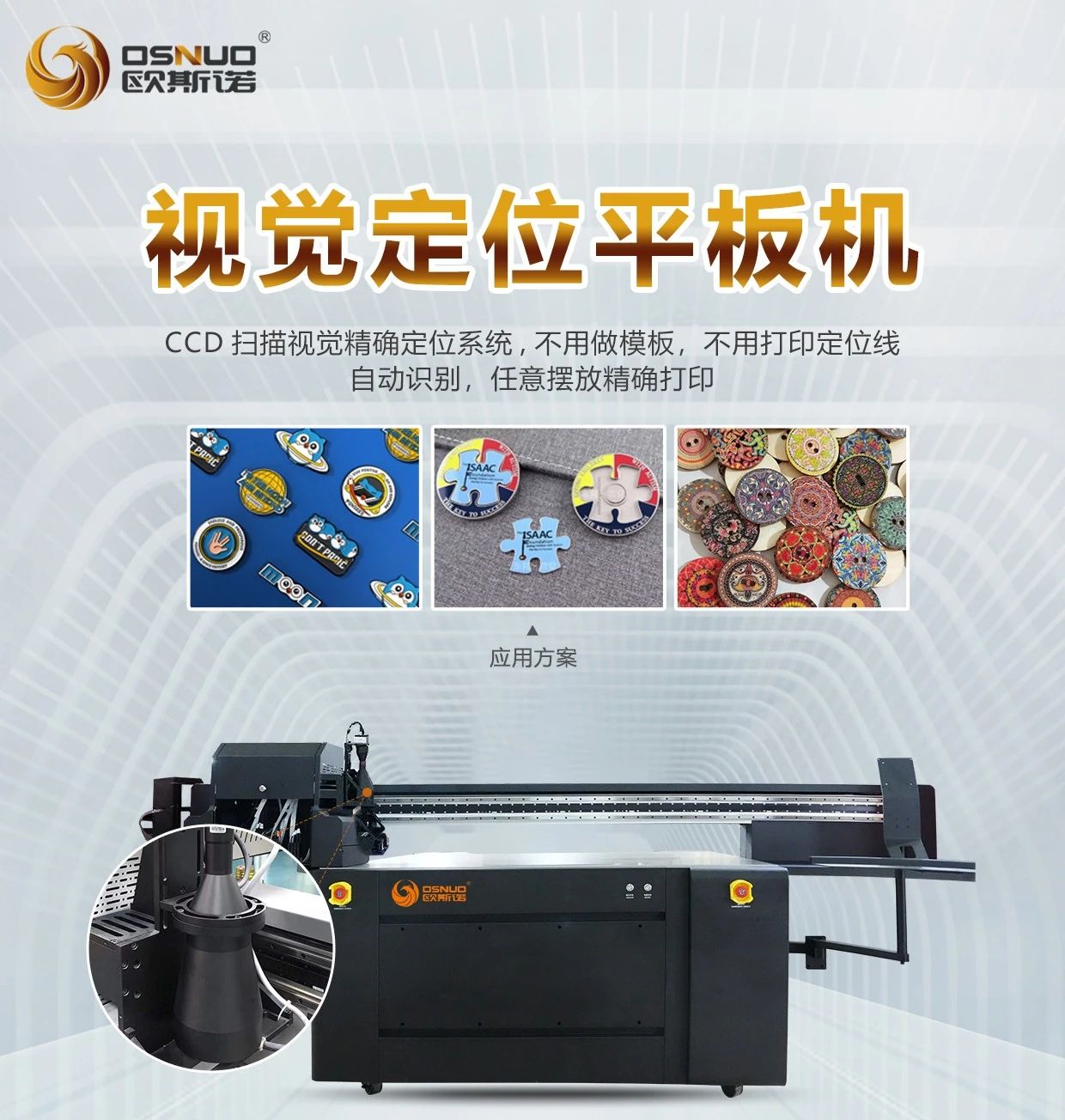

Material property: determines whether there is a matching coating and whether it is suitable for jet printing with UV flat-panel printer. In this respect, you can consult the salesman of UV flat-panel printer manufacturer, or you can determine it after proofing.;

Material cost: uv flat-panel printing is mainly based on personalized small batch customization, combined with bronzing, frosting, matte, 3D relief texture and other processes, the product has high added value and is suitable for products with higher profits. Therefore, users need to choose the most suitable equipment and printing method after considering cost accounting.

Second, choose and buy equipment

Manufacturer: The user can judge from the business license whether it belongs to a manufacturing enterprise or not, and the operating time of the manufacturer can ensure the research and development capability, product quality and after-sales service guarantee of the machine.

Agent system: the brand sales and service system is perfect and has certain service ability;

Brand awareness: you can also refer to the application and popularity of UV tablet machine in the market, but this reference is not absolute, and the key depends on the ability of manufacturers in technical application, solution and service; ;

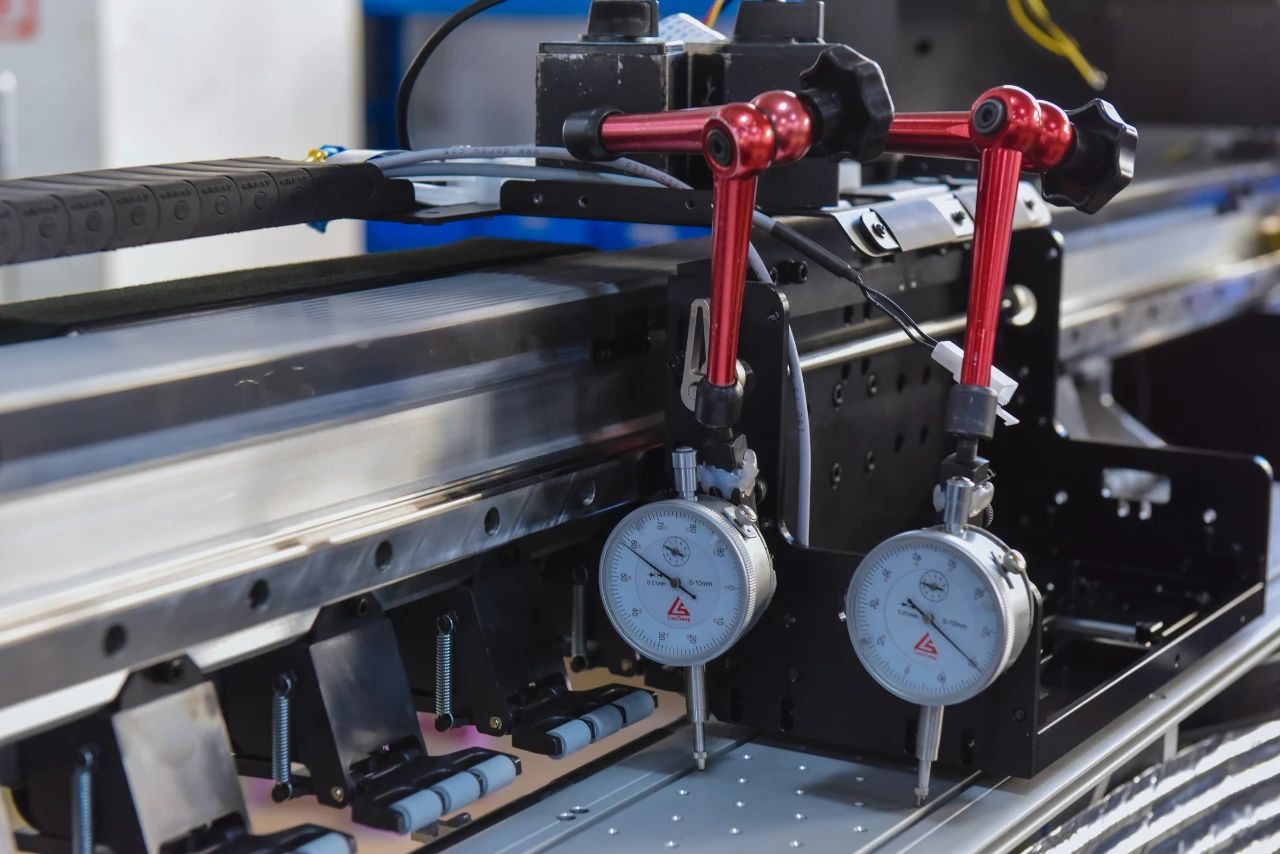

Equipment configuration: the core configuration such as nozzle, curing lamp, screw, guide rail, gantry milling and picture processing system need to be basically understood, which is conducive to smooth production in the later period.

After combining the above two factors, the user should consider whether the order quantity is full or not, and also have a determination to study and study. Nothing in the world is easy, and nothing is unattainable. If you look hard, you will get something.