Ink jet printing and metal effect

Inkjet Printing and Metal Effect

With the development of hardware and software technology, metal effects are easier to obtain than ever before. What do you need to know to get more business?

High-end effects in printed matter, such as bronzing or metallic effects, seem to be only the products of luxury brands that appeared only yesterday. The process of making these effects is both expensive and time-consuming, so only those brands with budget and influence, such as high-end cosmetics brands, will really use these effects.

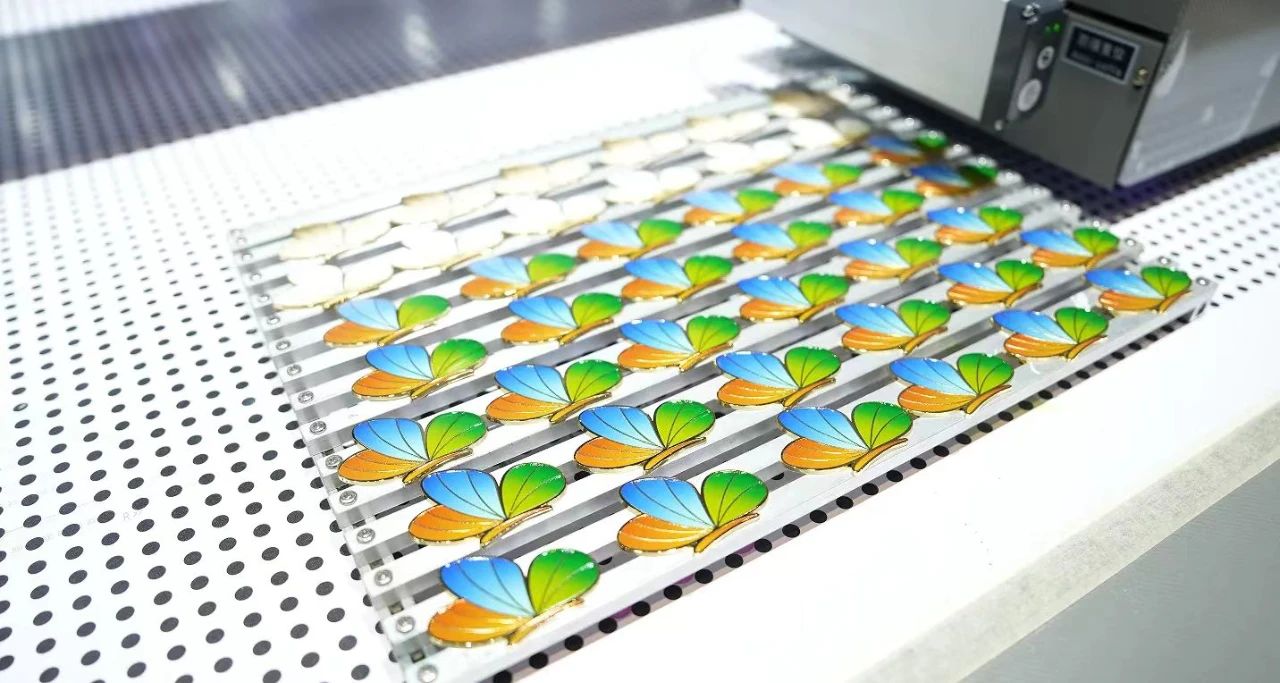

However, with the explosive innovation of digital decoration technology, all this began to change.

In terms of hardware and software, the metallic effect of printed matter is easier to obtain than ever before, which opens the door to creativity for brands of all sizes and types and makes them stand out. Not only packaging, but also direct mail, brochures and lawn signs, these effects are constantly emerging.

Several advances have especially promoted the development of metal effect in the field of printing, and will promote more significant growth in the next few years.

Innovation brings opportunities.

Metal media are usually used to add a touch of elegance to signs and packaging graphics. The progress of UV printing technology gave birth to special media and substrates, which made the metal effect easier to obtain. "The appearance of metallic ink can be reproduced by using a substrate with metallic luster. These materials include aluminum foil, paper and vinyl materials, as well as harder materials, which provide a substrate that can naturally reflect light. ...... In addition to the traditional metal appearance, reflective and holographic materials can also create dynamic and eye-catching effects, which will change with the audience's perspective and lighting conditions. "

The application of white ink makes the reflective materials display more space. Mark Geeves, sales and marketing director of Color-Logic, said, "white is the new gold. In the past, there were many problems in pushing white ink into the printing head, but with modern white ink, we see more and more people turning to printing white ink on reflective materials. There are not so many problems with mixing and blockage, and it looks better. "

He pointed out that white ink is more and more easy to use on various printing machines, cleaner and brighter, with improved opacity and good adhesion. Nowadays, many times, you can print CMYK on white and then print CMYK on it-there are many interesting things happening.。

Innovation is not only reflected in ink, substrate or hardware. Software also needs to be considered, and the progress in software is equally remarkable. Brooks pointed out: "The quality of the image depends on RIP ... An effective RIP can optimize the design for special media and create impressive effects by maximizing the effects of existing materials and the capabilities of printing machines."

Put into practice

Although it is a good thing to talk about technological progress making metal effects easier to obtain, what will it look like in practice?

Metal effect is not only suitable for packaging. Using metal effects to create eye-catching wall decoration can help brands define space in innovative ways.

Houston Sticker, headquartered in Houston, Texas, has witnessed the development of metal effects in recent years. Roy Garcia, the founder of the company, pointed out: "Our main application is to help customers promote the products of the company's brand, including label printing and QR code stickers. 25% of our customers use metal effects, and some customers also use metal effects in large quantities. "

Jeff Parker of Saskatoon 24 Hour Signs, Saskatoon, Canada, does less work, but his application is not the typical metal work you might think. He pointed out: "Our main products are various sizes of Coroplast and HIP (high impact polystyrene) signs. We produce inserts for A-frame, fence sign and lawn sign. ..... I think less than 5% of our applications use metal materials. "

In practice, Parker pointed out that most of the metal effects he saw came from printing on reflective vinyl. "However, we also provide metal effects by printing on a single color with glossy ink on UV, thus creating a double color that looks like a metal effect." "

Everyone agrees that one of the most challenging links to achieve a good metal effect is the initial design and file setting. The Pan Tong guide used by designers for metallic colors is printed on an offset press, and the color is not accurate. What printers have to do is to print their own color books, which will be printed on the same printing machine as the job, and not only use CMYK, but also use all the coatings and effects. "

Garcia agrees with this view and points out that the most challenging part of the metal effect for his business is the setting of documents. "When you handle different assignments in layers, you must pay attention to all aspects of the settings, so that you won't forget to specify spot colors or add luster effects. You need to pay attention to details and make sure that all links are ready to achieve perfect printing results. "

Do you have any suggestions for wide-format printers who are interested in adding metal effects?

Garcia said, "First of all, we should find an excellent supplier with metal media in stock. Once you start providing metal effects, you may find that you need to go back to the supplier more frequently and then invest immediately. Start making print samples for your top customers. Make sure to post your work on social media. Go one step further and help your business stand out by incorporating metal effects. "

Secondly, Parker said, "Practice, practice, practice again. It's hard to do this, but once you do it, nothing can match it. Metal effect, like any other form of decoration, will be amazing if used properly. People like' sparkling'-it's as simple as that ".

Next, Brooks pointed out that one thing to remember is to have the right partner to fully support the new application. "At any time, users are using new features to expand their business. When it is necessary to integrate new technologies and methods into existing workflows, it is always beneficial to cooperate with companies that will go with you every step of the way and are committed to ensuring your success. This may not be the cheapest initial choice, but when you have a' partner' relationship instead of a' supplier' relationship, the return will be even greater. "

Geeves said: "Do it first, don't wait for the work with metal effect-just show them what they didn't expect." Show them that you can make unique works-people will remember them. As for embellishment (such as metal effect), it has nothing to do with the return on investment. It's the customer's response. Can this product make the brand different? " He suggested making unique samples to show different metal effects and substrates, and even using customers' old works when possible, so that customers can understand how metal effects can improve publicity activities and enhance brand awareness and recognition.